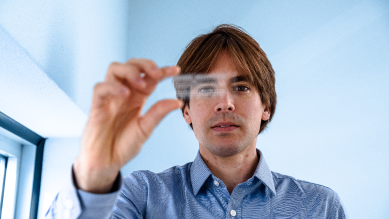

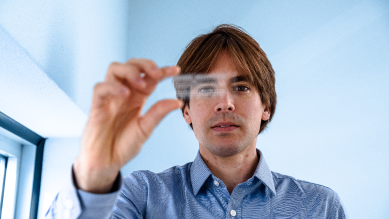

PROTOTYPING SERVICE

Our high quality prototyping service for microfluidics.

Transfer your assay or concept into a microfluidic-based product to get a good picture of your product.

Design support for the best prototyping result

Before prototyping, a comprehensive design review is essential. Micronit's experienced design team evaluates your concept for effectiveness and scalability, providing actionable feedback. Our goal is to smooth the transition from prototype to market-ready product while maintaining high quality. We view our design support as a continuous partnership aimed at optimizing your product for success.

Our experts will guide you through the process.

The variety of capabilities and available materials or reagents can be dazzling. Micronit will help you in customizing and optimizing your prototype in the right material and with prototype techniques with scalability in mind when desired. With years of experience in prototyping, contract development and contract manufacturing we can smoothly develop your prototype into a market ready product whether it is a microfluidic component or lab-on-a-chip based consumable.

A balanced approach between speed and quality

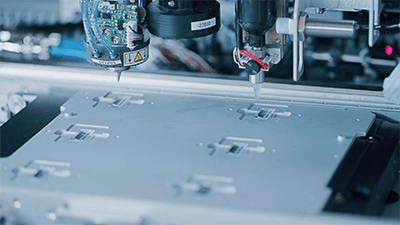

We've designed our prototyping service to strike the perfect balance between speed and quality. With all the required expertise in-house, Micronit can seamlessly transition your prototype design to a wafer-based production line. This operational efficiency allows for quick lead times without compromising quality. For clients seeking ISO 13485-certified product development and manufacturing, this is offered as an integral part of our product development services, but optional for prototyping.

CAPABILITIES

Discover your limits, explore our capabilities

Thanks to our quality prototyping service, we can provide you with a good understanding of your product in a short amount of time. We have all the necessary capabilities in-house. If you want to know more about our manufacturing capabilities please download our capabilities overview.

Below you can view materials, sizes and type of prototypes that are typically used. For alternative please get get in touch with us.

We provide fast prototyping service for the following materials:

- Glass

- Polymer

- Silicon

- Various materials for customized interfacing

We provide prototyping service for the following formats:

Typically starting with

- 6in round

- 6in square

- 8in round wafers

Separated in various prototype sizes

- Typical 15x15 to 45x15 footprint in glass

- Microscope slide

- Other ISO_22916_2022 chip layout standards

- Custom sizes

We provide prototypes for:

Microfluidic Applications

- Droplet-based microfluidics

- Cell sorting chips

- Micromixing and microreactors

- Microfluidic-based sensing

- Microfluidic interfacing

Analytical Techniques

- Optical flow cells

- Electrical impedance spectroscopy

- Capillary electrophoresis

Medical and Pharmaceutical Applications

- Drug delivery

- Lab-on-Chip

- Organ-on-Chip

Industrial Applications

- Spray and sheet nozzle chips

- Enhanced oil recovery

PRODUCT DEVELOPMENT

Go beyond prototyping, start developing

We are an independent Contract Development and Contract Manufacturing partner that delivers high-quality microfluidic-based products. The possibility for customizing your microfluidic device are endless. We know the complexities of designing, testing, and manufacturing microfluidic devices. Our goal is to provide you with the highest quality products that meet your specific requirements, from the initial concept to the final production.

Whether you need a simple chip design or a complex multi-layered product, we have the expertise and technology to bring your ideas to life. Our teams are well-aligned and experienced in making successful transfers to production, resulting in higher quality products and faster time to market. If you want to know more about our extensive product-development services, please don't hesitate to contact us